Casting

Week 13

Soft Robotics

Soft robotics is a field which focuses on making robots from a pliable material which can bend easily. I have wanted to explore this field a for a long time, so I have decided to make a fish mold. Inspired by the robotic fishes you can buy in toy stores, the idea was to make a silicone fish which could wiggle its tail and swim. I will not be making the moving fin; however, I fill focus on finding the best material for the robot.

The Mold

I began by modeling a fish in Fusion 360. Until now, I have only made “functional parts” and have never modeled a 3D prop. Following a fish sculpting tutorial, I made a simple model of a clownfish.

To make the mold, I subtracted the model from a cuboid-shaped box. Splitting it in the middle, I ended up with two identical halves of the mold. By adding fiducial (alignment) studs, I will be able to close the mold precisely while casting. Unfortunately, forgetting about nozzle tolerances made this a bit more difficult, as I didn’t downsize the female fiducial marker. Luckily, this wasn't a huge problem in the later steps.

Materials

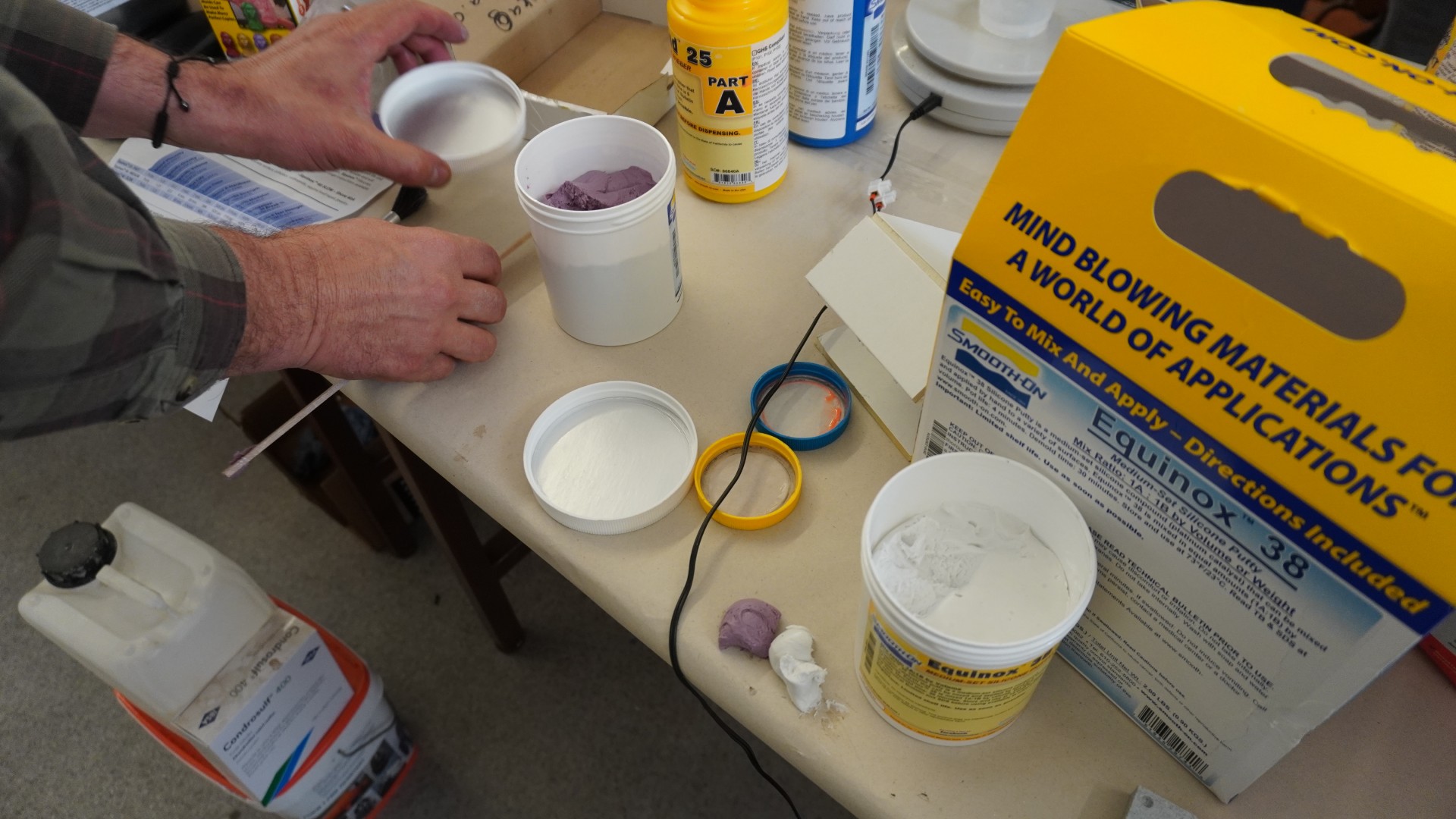

The first material I will try is the Equinox™ 38 MEDIUM from Smooth-On. It is a light purple silicone putty with a cure time of only 30 minutes. Its mixing ratio is 1:1 by both weight and volume. This makes the measurements quite easy and flexible. Both advantage and the disadvantages of this material is its higher shore rating of 38A. This means the putty will be much stiffer when cured than other silicone products.

The second material is the Dragon Skin™ 10 FAST from Smooth-On. It is a skin-safe silicone, meaning it is certified to be applied directly to the skin. The shore rating is 10A, which makes it much softer than the Equinox. One downside is a 75-minute cure time. Since the silicone is white, I will add a blue coloring with a hint of blue glitter. Again, the color and the glitter powder are mixed with one part of the silicone before activating it in a 1:1 ratio (by weight or volume).

Molding Process

We will be making a cast from the Equinox silicone putty. First, we spray the mold with a release agent. This will help demold the fish, once it’s cured. For an effect, we sprinkle silver glitter onto the mold and brush it into the mold. Our professor recommended that make up brushes work the best. In the second step, we mix both parts of the Equinox silicone in a 1:1 ratio. We have decided to match the weight; however, volume matching will produce the same result as noted before.

Glitter in the mold. Will be brushed by a make up brush.

Mixing of the Equinox (seen at the bottom).

Now we need to move fast. With a pot life of 4 minutes, we need to assemble the mold in time. We first begin by filling the fin holes using a spatula (the flat end of tweezers works quite well). This takes the longest time as we need to be sure we squeeze enough material into the grooves. Next, we’ll take advantage of the putty consistency of Equinox and fill the rest of the mold. The idea is to put a bit of excess material in and clamp the mold in a vice. This squeezes out the extra material and fills the mold perfectly. Furthermore, using a vice forces the mold together and almost completely remedies the mistake in print tolerances.

Spatula (tweezers) used to push the material into the fins.

The mold is filled with excess putty.

The mold is squeezed using a vice to distribute the Equinox evenly.

When the first fish is cured, we will try casting it in another material. This time, we’ll use the Dragon Skin silicone. The biggest difference is its consistency. We are now working with a white liquid, so the first step is to add some color. I put a bit of blue color into one part of the silicone and sprinkled blue glitter for a more interesting result.

After thoroughly mixing in the color, we match a 1:1 ratio of both silicone parts by weight. Again, in the case of Dragon Skin, matching by volume produces the same result. We need to be careful to introduce as few bubbles in the mixture as possible. Luckily, with 8 minutes, the pot life of the Dragon Skin is twice as high as that of Equinox.

Consequently, the mold is first sprayed with release agent. Next, we lay both sides of the mold on the table and push the silicone into the fins (a spatula works the best). Now, we pour the silicone into the fish. Make sure to put in excess so that squeezing the mold fills the model evenly. We clamp it in the vice and wait 75 minutes. Put a tiny piece of paper under the mold, as the silicone will drip down.

Release agent in a spray.

To facilitate the curing process, you can put the mold in hot water after the Dragon Skin becomes solid enough. I have done this after about 35 minutes. After 15 minutes in hot water, I could demold the fish with ease. When opening the mold, it is important to free the fins first. The best way to do so is by moving slowly and observing what the mold does. Unfortunately, one fin of the Equinox fish was torn by improper demolding.

Sppeding the curing process by placing the mold in a hot bath.

The Results

The results are two fish. One in a tougher but better casted material (Equinox), and the other in a more flexible, but lacking detail (Dragon Skin). For soft robotics applications, I will prioritize flexibility over appearance. Albeit the Equinox can stretch up to 430% before it breaks, it is overshadowed by the Dragon Skin’s 1000% elongation-at-break ratio.

Final results.