Every engineer has at least one project that was in one form or another been put on the backburner. For the last few years, the amount of projects I am working on has been steadily increasing, while the list of finished projects remained the same. The How To Make (almost) Anything (from now on I’ll call it HTMAA) course is a perfect opportunity to take at least one project to completion.

The only question remains, which project to choose? One thing I wanted to do for a long time was to design my own nixie tube / X-ray tube. Both features work with vacuum systems and machining tools, techniques I have very little experience in. I am studying my Bachelor’s program in the Czech Republic, which is the only country where nixie tubes are still manufactured by Dalibor Farny to this day.

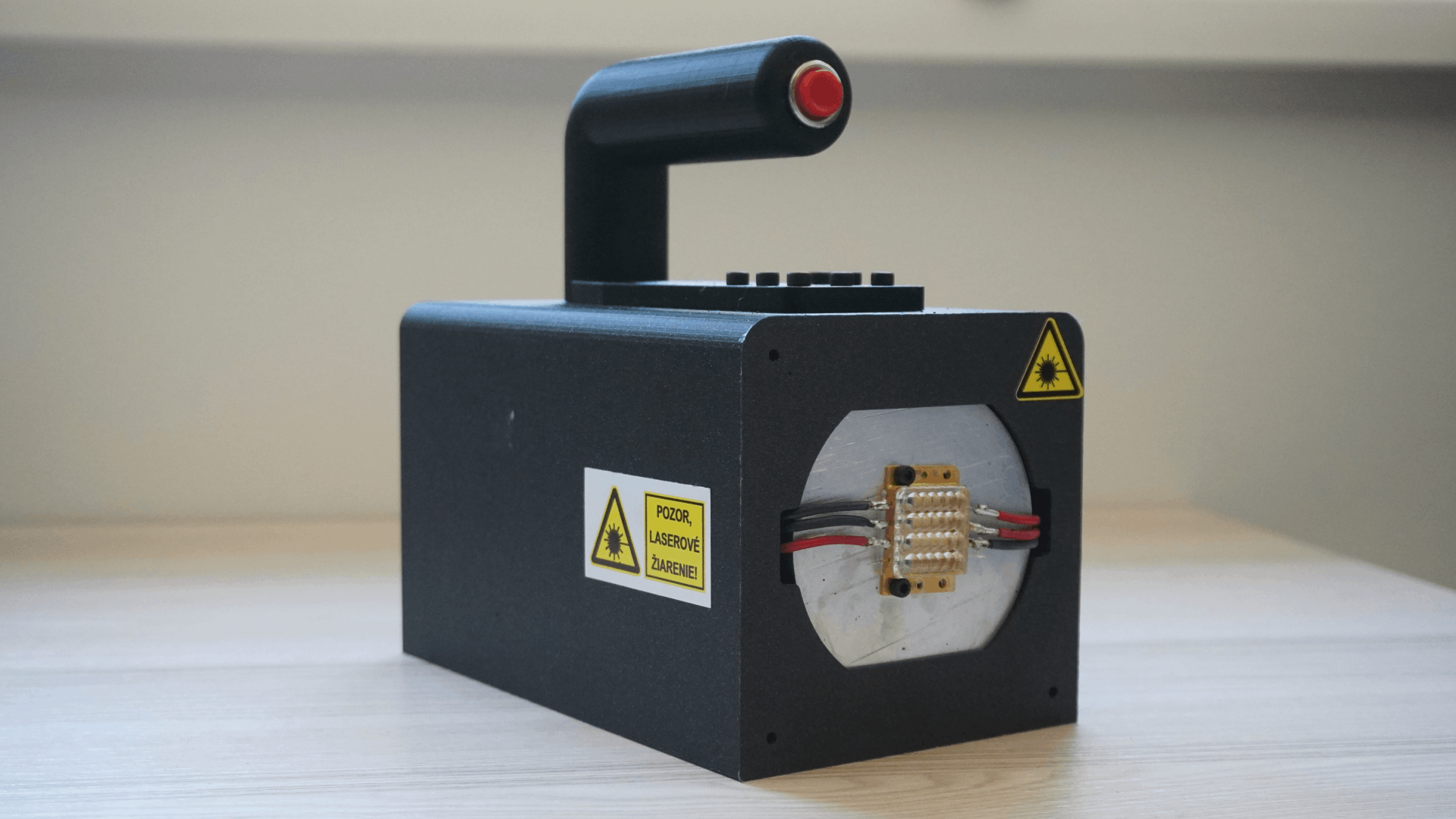

After thinking for a few days, I have set my mind on finishing an ongoing project of mine rather than starting a completely new one. A project I am talking about is the Portable Handheld Battery-Operated Continuous Wave (CW) Laser. I know, a mouthful of technical terms, but I assure you, every single one of them is crucial for the project’s success and will come important later.

I started working on the laser in my senior year of high school. I managed to get a basic prototype working and even gave an interview about it to a renowned Slovak journal, Aktuality.

To understand the goals for this project, we need to go back to 2021, which marks the beginning of my laser hobby. My fascination began by watching Drake Anthony’s videos on his YouTube channel named styropyro. After talking to many hobbyists in the laser community I bought my first laser diode, the Sharp 488nm 55mW.

Before I continue talking about lasers, it is important to note that LASERS ARE DANGEROUS! And I mean it. In the laser community there are numerous recorded cases, where an individual has been permanently blinded due to negligence of safety standards. Lasers are not toys and laser protective goggles should be worn at ALL TIMES every instance you are in the vicinity of a laser! These articles are not safety advice and should not be viewed as such.

Before I bought my first laser diode, I have spent around two years in the laser community. Additionally, it took me two more years to get access to a lab, where I was able to test the OD (Optical Density – how much light do the glasses absorb) rating of my goggles before I powered up any of my lasers. Hence a special thanks goes to the International Laser Center in Bratislava for helping me test my laser goggles.

After I gained confidence in my knowledge and my safety equipment, I ordered a new laser diode. I chose the NDB7A75 3.5W 445nm from Nichia. With 3.5 Watts of optical output power, this laser falls within the strongest ANSI (American National Standards Institute) classification of lasers – Class 4. This laser is 7 times more powerful than the threshold for Class 4 lasers. This means the laser can easily cause permanent blindness if not treated carefully!

After working with the 3.5W Nichia diode for a while, I have finally felt confident to order the PLPM4 450 60W 450nm laser diode array from OSRAM. This monstrous diode boasts 60 Watts of total optical output and consists of 15 smaller laser diodes. This type of array is commonly used in DLP projectors.

The driver of the laser was based on the LM338 adjustable linear voltage regulator. With the linear approach came simplicity of the driver design, or so I thought. I have tried to get the prototype running correctly, but I kept encountering issues. It seemed that the voltage on the adjust pin of the regulator was constantly off, which hindered the operation of the driver. I believe there was an unwanted EMI pickup in the long cables leading to the regulator. Even if I tried to keep the grounding wire as close as possible to the other cables, the issue persisted. This has led me to start the development of the second prototype.

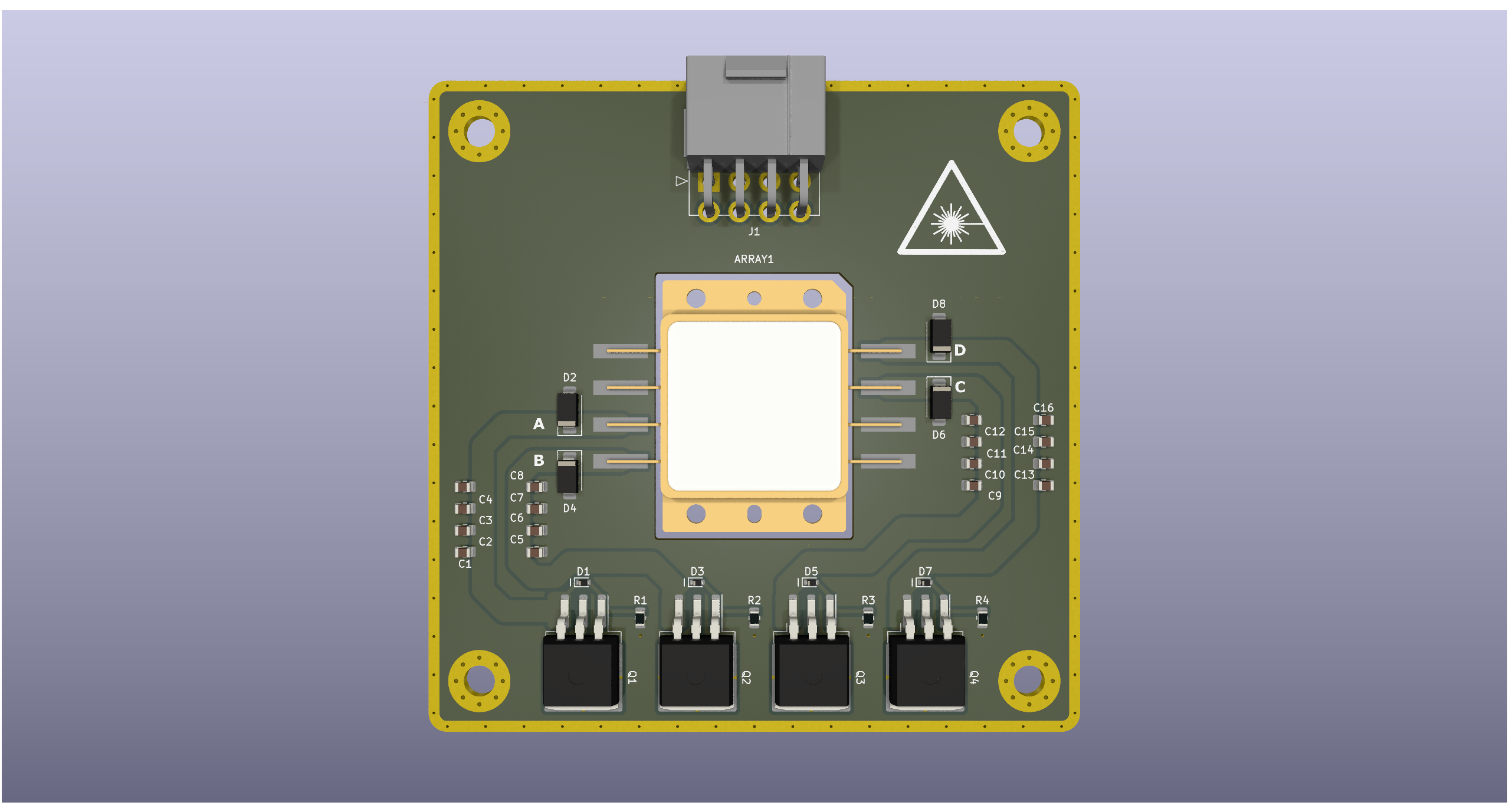

The next prototype aimed to integrate the design onto printed circuit boards (PCBs). The main driving force behind this effort was better signal integrity and reduced EMI pickup, as experienced by the previous version. The design consisted of a Laser Array Interface Module, whose main advantage was the possibility to swap different laser drivers. Additionally, ESD protection was introduced to minimize the risk of damaging the driver.

Next is the Laser Array Driver Module which featured the same linear approach, however, with improved signal integrity. The design required a resistor of a specific value, for setting the correct laser diode current. To address the power losses in the resistors, I have designed them on a PCB. The layout of the copper tracks was done using the Peano-Hilbert space filling curve, an approach I have never seen before. The resistor board was plugged into the driver module and the entire stack was cooled by an external fan.

The design however was never ordered due to later realization of the enormous power losses caused by the linear approach. Furthermore, other design topologies would allow for more control and safety of the device.

The design however was never ordered due to the later realization of the enormous power losses caused by the linear approach. Furthermore, other design topologies would allow for more control and safety of the device.

To address the issues, I have researched other design topologies. To speed up the process, I have already assembled a few prototype boards that successfully verified the functionality of critical parts of the design. I believe this project’s qualities encompass the requirements for the HTMAA course perfectly. I hope you are as excited as I am to go on this journey, to make one of the strongest battery-operated lasers in the entire world!